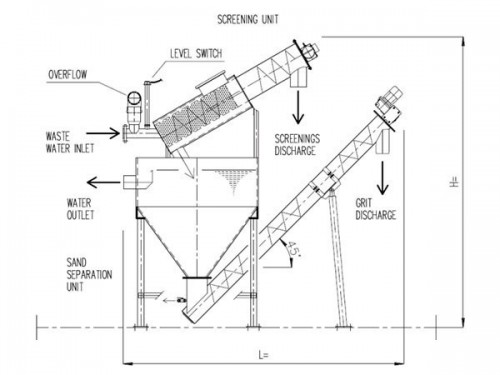

Sludge Screens, Grit Separation and Treatment Unit

Features

HSF is designed for a wide range of waste water flow rates with different sedimentation capacities. The possibility to choose the size of the screen perforation/slots, as well as cross section and length of the tank, is the assurance for thecustomer that he will obtain the right solution to his problem. The machine comes in high-quality, industrially manufactured, standard modules, ready for comfortable on-site assembly if requested. The screen section of the plant is equipped with a compacting device in the upper part for a volume reduction of the screenings of up to 35%. A washing system for the reduction of organic matter in the screenings is available on request. The shaftless screen screw, which is manufactured in an innovative, patented process, ensures smooth operation without clogging even in presence of fibres.

Benefits

Decreased infrastructure costs.

Easy on-site machine assembly using standard tools. Reduction of intermediate storage costs.

Best footprint-net volume ratio for this type of machine.

Durable heavy-duty shaftless screws.

A self-adjusting scraper device allows for limited water removal in any flow conditions.