Short Lead Time for Sludge Dewatering Unit - Screw Press sludge dewatering machine – Haibar

Short Lead Time for Sludge Dewatering Unit - Screw Press sludge dewatering machine – Haibar Detail:

Mechanical Principle

The initial section of dewatering drum is Thickening Zone where the solids-liquid separating process takes place and where the filtrate will be discharged. The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, increasing the internal pressure of the drum. At the end, End Plate further increases the pressure so as to discharge dry sludge cake.

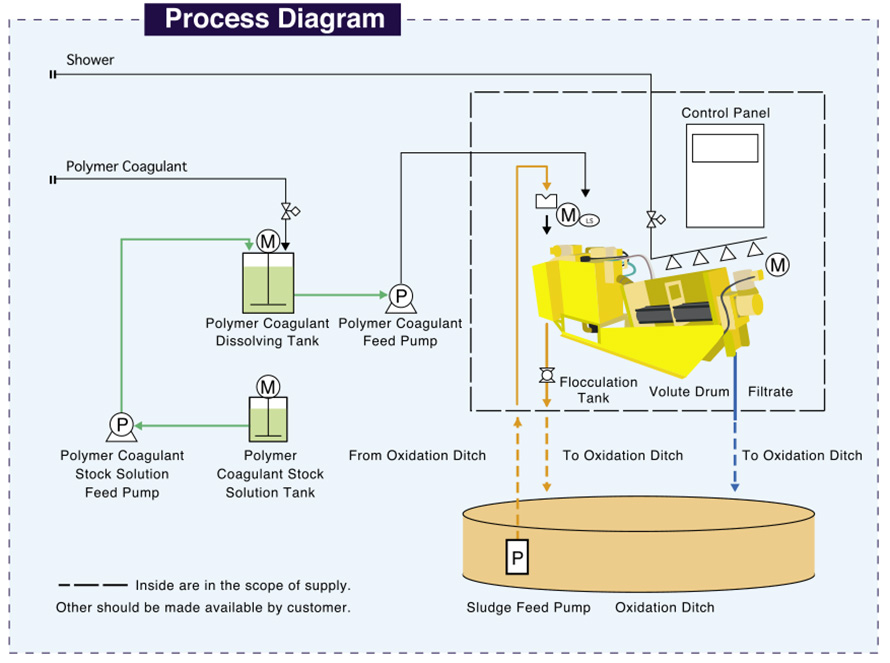

Process Diagram of the Vloute Dewatering Press

Sludge, first fed into the Flow Control Tank, flows into the Flocculation Tank where polymer coagulant is added. From there, the flocculated sludge overflows into the dewatering drumwhere it is filtered and compressed. The entire operation sequence, including sludge feedcontrol, polymer makeup, dosing and sludge cake discharging, is controlled by the built-in-timer and sensors of the Control Panel.

Product detail pictures:

Related Product Guide:

Our concentrate on should be to consolidate and enhance the quality and service of present products, meanwhile consistently produce new products to meet unique customers' demands for Short Lead Time for Sludge Dewatering Unit - Screw Press sludge dewatering machine – Haibar , The product will supply to all over the world, such as: Madrid, India, Peru, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!