High definition Thickeners In Cosmetics - Drum Thickener – Haibar

High definition Thickeners In Cosmetics - Drum Thickener – Haibar Detail:

Features

Higher than 96% solid recovery rate

Steady operation with little to no noise

Easy operation and maintenance ensures a long service life.

The perfect thickening effect can easily even out the varying sludge concentrations.

A 40% output capacity is larger than other machines that occupy the same amount of floor space.

The costs of land, construction and labor are all saved as this machine takes up less floor space with its simple structure, small flocculent requirements and fully automatic operation.

Parameter

| Spec. | HNS-5 | HNS-10 | HNS-20 | HNS-30 | HNS-40 | HNS-50 | HNS-60 | HNS-80 | HNS-100 | ||

| Machine Frame Material | Standard | Stainless steel(SUS304) | |||||||||

| Option | Carbon steel(SS400/SS41), stainless steel(SUS316), other special materials | ||||||||||

| Filter Opening(micron) | 30~80 | 30~80 | 30~80 | 30~80 | 30~80 | 30~80 | 30~80 | 30~80 | 30~80 | ||

| Treating Capacity(m3/hr) | 2~6 | 6~12 | 11~23.5 | 22~32.5 | 33~42.5 | 41~52 | 45~63 | 61~83 | 80~105 | ||

| D.S Dried Sludge(kg/hr) | 40~70 | 90~120 | 150~220 | 240~310 | 260~420 | 290~510 | 360~600 | 540~900 | 620~1250 | ||

| Sludge Outlet Consistency(%) | 3.5~11 | 3.5~11 | 3.5~11 | 3.5~11 | 3.5~11 | 3.5~11 | 3.5~11 | 3.5~11 | 3.5~11 | ||

| Power Consumption(HP) | Standard | Driving Motor(Frequency control) | 1/2 | 1/2 | 3/4 | 1 | 1 | 1 | 1*2 | 1*2 | 1*2 |

| Flocculator Tank Motor | 1/4 | 1/4 | 1/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 1 | ||

| Option | Washing Pump | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 2 | 2 | 2 | |

| Lower Collecting Tray for Pressed Filtrate | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||

| External Dimensions(mm) | L1 | 2075 | 2085 | 2525 | 2525 | 2545 | 3015 | 2525 | 2545 | 3015 | |

| L | 2708 | 2808 | 3344 | 3448 | 3548 | 4048 | 3498 | 3648 | 4148 | ||

| W | 938 | 1038 | 1058 | 1078 | 1128 | 1128 | 1800 | 1900 | 1900 | ||

| H | 1206 | 1340 | 1458 | 1535 | 1595 | 1845 | 1535 | 1595 | 1845 | ||

| Weight | 300 | 450 | 700 | 1050 | 1220 | 1320 | 1450 | 2000 | 2560 | ||

Working Principle

The slurry and flocculating polymer are poured into the conditioning tank of the rotary drum sludge thickener for uniform agitation. Then, the hardly dehydrated floc granules are formed, and flow into a drum for sludge-water separation. The conditioned sludge is guided into the fine mesh of the drum. A large amount of supernatant free water will be filtered, when a centrifuge rotates slowly under conditions of the rotational speed of 22r.p.m. and the power of 0.37kW per unit.

As a result, the slurry is thickened. The processing capacity of our rotary drum sludge thickener is improved, and the operating time is shortened. The separated sludge can highly reduce the load of the belt for permeating water. Meanwhile, the sludge group is constructed firmly. No sheet-flood or side-overflow phenomenon will occur. Then, the dehydration efficiency is enhanced, and the water content rate is lowered. After separation, the solids content of the free water varies from 0.5‰ to 1‰, which is closely related with the dosage and types of the polymer.

The semi-centrifugal rotary drum thickener can filter the free water by means of external force. It has high requirements for the polymer and the binding force of sludge. In comparison with the belt thickening machine, our rotary drum sludge thickener can offer the thickened sludge with lower water content. The sludge with its water content of over 1.5% is a better choice.

Side View of the Thickening Equipment

Side View of the Thickening Machine

Front View of the Thickening Apparatus

Screen in the Rotary Drum of the Thickener

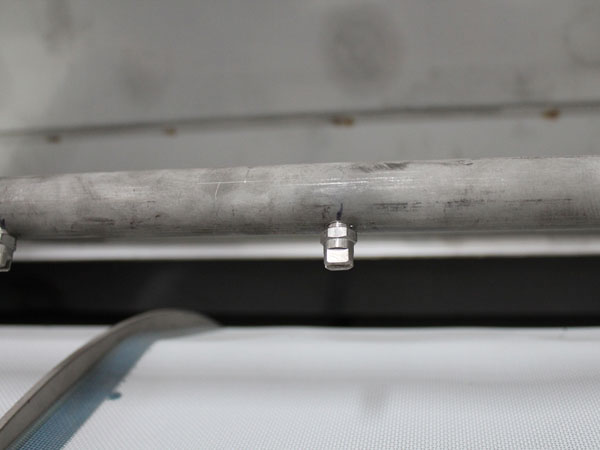

Stainless Steel Nozzle Imported from Japan

Cleaning Hose

The filter cloth imported from Germany features great air permeability, practical use, and long lifespan.

Cargo Examined by Japanese Customers before Delivery

The sludge outlet and perspective window of the HNS-80 series rotary drum sludge thickener are specially designed for observing the operation of our equipment.

Product detail pictures:

Related Product Guide:

All we do is always associated with our tenet " Customer first, Trust first, devoting on the food packaging and environmental protection for High definition Thickeners In Cosmetics - Drum Thickener – Haibar , The product will supply to all over the world, such as: Spain, Ethiopia, Bangladesh, We have a dedicated and aggressive sales team, and many branches, catering to our main customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!