Factory wholesale Vertical Filter Press - HTE3 Heavy Duty Belt Filter Press (Gravity Belt Type) – Haibar

Factory wholesale Vertical Filter Press - HTE3 Heavy Duty Belt Filter Press (Gravity Belt Type) – Haibar Detail:

HAIBAR’s belt filter presses are 100% designed and manufactured in house, and feature a compact structure in order to treat different types and capacities of sludge and wastewater. Our products are well known throughout the industry for their high efficiency, low energy consumption, low polymer consumption, cost saving performance and long service life.

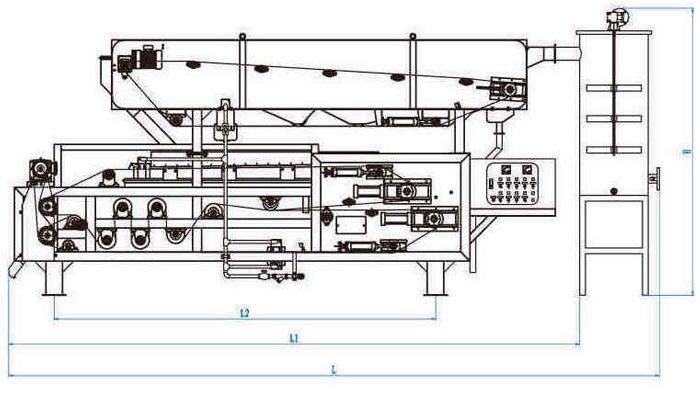

An HTE3 series belt filter press is a heavy duty filter press featuring a gravity belt thickening technology.

Features

1. Integrated gravity belt thickening and dewatering treatment process

2. Ultra-long thickening and dewatering works on nearly all sludge types.

3. Wide range and large treatment capacity applications

4.The best performance is found when the inlet consistency is 0.4-1.5%.

5. Installation is easy due to the compact structure.

6. Automatic, continuous, simple, stable, and safe operation

7. Environmentally friendly operations come through the low energy consumption and low noise emissions.

8. Easy maintenance leads to long term operation.

9. The patented flocculation system reduces polymer consumption.

10. The rollers come with up to 9 segments and feature an increased diameter, high shear strength and a small wrapped angle press to offer a maximized treatment effect and achieve an extremely low water content rate.

11. The pneumatic adjustable tension achieves ideal effects that are in full compliance with the treatment process.

12. A galvanized steel rack can be customized when the belt width reaches more than 1500mm.

Main Specifications

| Model | HTE3 -750 | HTE3 -1000 | HTE3 -1250 | HTE3 -1500 | HTE3 -2000 | HTE3 -2000L | HTE3 -2500 | HTE3 -2500L | |

| Belt Width (mm) | 750 | 1000 | 1250 | 1500 | 2000 | 2000 | 2500 | 2500 | |

| Treating Capacity (m3/hr) | 11.4~22 | 14.7~28 | 19.5~39 | 29~55 | 39~70 | 47.5~88 | 52~90 | 63~105 | |

| Dried Sludge (kg/hr) | 60~186 | 76~240 | 104~320 | 152~465 | 200~640 | 240~800 | 260~815 | 310~1000 | |

| Water Content Rate (%) | 65~84 | ||||||||

| Max. Pneumatic Pressure (bar) | 6.5 | ||||||||

| Min. Rinse Water Pressure (bar) | 4 | ||||||||

| Power Consumption (kW) | 1 | 1 | 1.15 | 1.9 | 2.7 | 3 | 3 | 3.75 | |

| Dimensions Reference (mm) | Length | 4650 | 4650 | 4650 | 5720 | 5970 | 6970 | 6170 | 7170 |

| Width | 1480 | 1660 | 1910 | 2220 | 2720 | 2770 | 3220 | 3270 | |

| Height | 2300 | 2300 | 2300 | 2530 | 2530 | 2680 | 2730 | 2730 | |

| Reference Weight (kg) | 1680 | 1950 | 2250 | 3000 | 3800 | 4700 | 4600 | 5000 | |

Note

1. Our company reserves the right to modify the above-mentioned specifications of this series heavy duty gravity belt thickening-dewatering belt filter press.

2. The treating capacity, dried sludge, and water content rate all depend on the varieties of sludge.

Customer case

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Factory wholesale Vertical Filter Press - HTE3 Heavy Duty Belt Filter Press (Gravity Belt Type) – Haibar , The product will supply to all over the world, such as: Iceland, Borussia Dortmund, Senegal, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.