China Manufacturer for Recessed Filter Press - Belt Filter Press Combined Rotary Drum Thickener – Haibar

China Manufacturer for Recessed Filter Press - Belt Filter Press Combined Rotary Drum Thickener – Haibar Detail:

HAIBAR’s belt filter presses are 100% designed and manufactured in house, and feature a compact structure in order to treat different types and capacities of sludge and wastewater. Our products are well known throughout the industry for their high efficiency, low energy consumption, low polymer consumption, cost saving performance and long service life.

An belt filter press is a heavy duty filter press using the featured technology of rotary drum thickening.

Features

1. Integrated rotary drum thickening and dewatering treatment processes

2. This machine carries out an ultra-long thickening and dewatering process for nearly all sludge types.

3. Wide range and large treatment capacity applications

4. The best performance is found when the inlet consistency is 1.5-2.5%.

5. Installation is easy due to the compact structure.

6. Automatic, continuous, simple, stable and safe operation

7. Environmentally friendly operation is achieved due to the low energy consumption and low noise levels.

8. Easy maintenance ensures the long service life.

9. A patented flocculation system reduces polymer consumption.

10. Press rollers with 9 segments, an increased diameter, high shear strength and small wrapped angle offer maximized treatment effects and achieve an extremely low water content rate.

11. The pneumatic adjustable tension achieves an ideal effect in full compliance with treatment processes.

12. A galvanized steel rack can be customized when the belt width reaches more than 1500mm.

Focus

Pneumatic Tensioning Device

The pneumatic tensioning device can realize the automatic and continuous tensioning process. In accordance with the site conditions, users can adjust tension by adoption of our pneumatic tensioning device instead of the spring tensioning tool. Coordinated with the filter cloth, our device can achieve a satisfactory rate of solids content.

Nine-Segment Roller Press

A maximized treatment effect can be offered, because of the press roller of up to 9 segments and the roller layout of high shear strength. This roller press can give the highest rate of solids content.

Applications

For achieving the best treatment effect, this series belt filter press adopts the unique frame-type and heavy-duty structural design, the ultra-long thickening section, and the roller with increased diameter. Therefore, it is extremely suitable for treating the sludge of low water content in different industries including the municipal administration, papermaking, polycrystalline silicon, palm oil, and more.

Cost Saving

Owing to low dosage and low energy consumption, our superior mechanical dewatering system can obviously help clients save much cost. Thanks to simple maintenance and operation, it has a low demand for operators, so that the human resource cost can be greatly reduced. Moreover, this product can offer an ultra high rate of solids content. Then, the total amount and transportation cost of the sludge can be enormously lowered.

Superior Quality

This series heavy duty rotary drum thickening-dewatering belt filter press is constructed from SUS304 stainless steel. It can be optionally designed with a galvanized steel rack upon request.

High Working Efficiency

Furthermore, our sewage sludge dewatering equipment can run continuously and automatically. It is equipped with a high-efficiency rotary drum thickener, thus being ideal for the thickening and dewatering of high-concentration sludge. Depending on its heavy-duty type structural design, this machine can provide the best operation effect among all dehydrators of the same kind. It features the highest solids content rate and the lowest flocculant consumption. In addition, our series heavy duty type sludge thickening and dehydrating machine can be used for thickening and dewatering all kinds of sludge on site.

Technical Parameters

| Model | HTE -750 | HTE -1000 | HTE -1250 | HTE -1500 | HTE -1750 | HTE -2000 | HTE -2000L | HTE -2500 | HTE -2500L | |

| Belt Width (mm) | 750 | 1000 | 1250 | 1500 | 1750 | 2000 | 2000 | 2500 | 2500 | |

| Treating Capacity (m3/hr) | 6.6~13.2 | 9.0~17.0 | 11.8~22.6 | 17.6~33.5 | 20.4~39 | 23.2~45 | 28.5~56 | 30.8~59.0 | 36.5~67 | |

| Dried Sludge (kg/hr) | 105~192 | 143~242 | 188~325 | 278~460 | 323~560 | 368~652 | 450~820 | 488~890 | 578~1020 | |

| Water Content Rate (%) | 60~82 | |||||||||

| Max. Pneumatic Pressure (bar) | 6.5 | |||||||||

| Min. Rinse Water Pressure (bar) | 4 | |||||||||

| Power Consumption(kW) | 1.15 | 1.15 | 1.5 | 2.25 | 2.25 | 2.25 | 4.5 | 4.5 | 5.25 | |

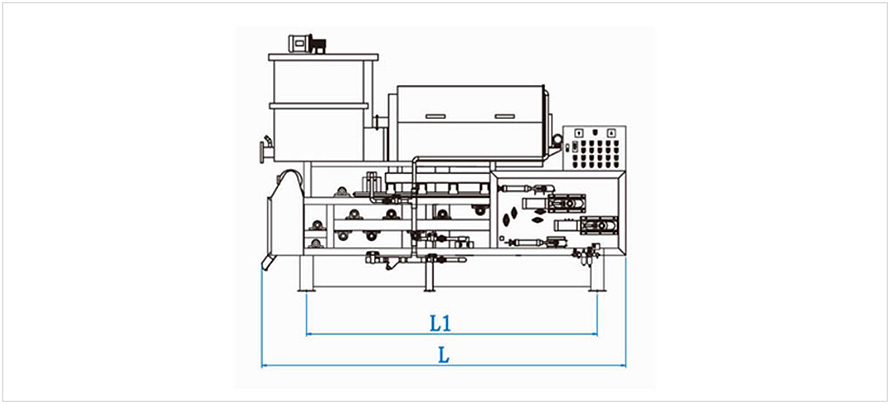

| Dimensions Reference (mm) | Length | 3300 | 3300 | 3300 | 4000 | 4000 | 4000 | 5000 | 4000 | 5100 |

| Width | 1350 | 1600 | 1850 | 2100 | 2350 | 2600 | 2600 | 3200 | 3200 | |

| Height | 2550 | 2550 | 2550 | 2950 | 3300 | 3300 | 3450 | 3450 | 3550 | |

| Reference Weight (kg) | 1400 | 1720 | 2080 | 2700 | 2950 | 3250 | 4150 | 4100 | 4550 | |

Attention

1. Our company reserves the right to modify the above-mentioned specifications of this series heavy duty rotary drum thickening-dewatering belt filter press.

2. The treating capacity, dried sludge, and water content rate are decided by the types of sludge.

Customer case

Product detail pictures:

Related Product Guide:

We always continually provide you with the most conscientious customer service, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for China Manufacturer for Recessed Filter Press - Belt Filter Press Combined Rotary Drum Thickener – Haibar , The product will supply to all over the world, such as: Latvia, Philippines, America, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.