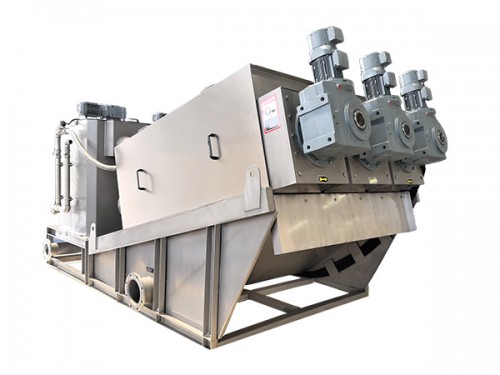

Automatic Sludge Dewatering Machine Screw Press for Inorganic Sludge Dehydrating

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we’re hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for Automatic Sludge Dewatering Machine Screw Press for Inorganic Sludge Dehydrating, We play a leading role in giving buyers with high-quality goods fantastic provider and competitive selling prices.

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we’re hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for screw press, sludge dewatering, Adhering to the principle of “Enterprising and Truth-Seeking, Preciseness and Unity”, with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective items and meticulous after-sales service. We firmly believe that: we have been outstanding as we have been specialized.

Mechanical Principle

The initial section of dewatering drum is Thickening Zone where the solids-liquid separating process takes place and where the filtrate will be discharged. The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, increasing the internal pressure of the drum. At the end, End Plate further increases the pressure so as to discharge dry sludge cake.

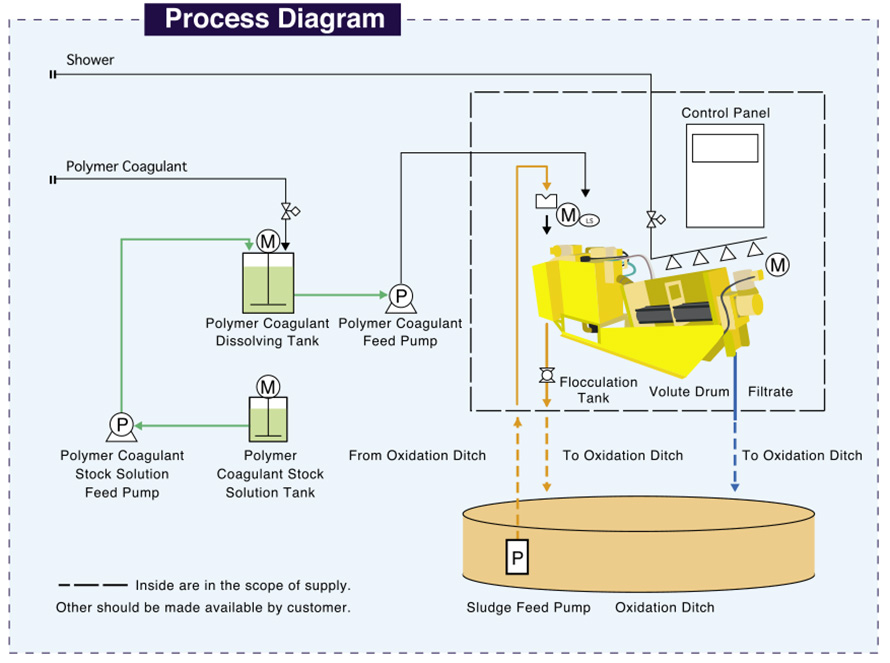

Process Diagram of the Vloute Dewatering Press

Sludge, first fed into the Flow Control Tank, flows into the Flocculation Tank where polymer coagulant is added. From there, the flocculated sludge overflows into the dewatering drumwhere it is filtered and compressed. The entire operation sequence, including sludge feedcontrol, polymer makeup, dosing and sludge cake discharging, is controlled by the built-in-timer and sensors of the Control Panel.

When the device is operated, the conditioned sludge flows into the flocculation tank and is pushed forwad the discharging end. With the gap between the thread of the shaft is getting more and more narrow, the pressure on the sludge is getting higher and higher.

When the device is operated, the conditioned sludge flows into the flocculation tank and is pushed forwad the discharging end. With the gap between the thread of the shaft is getting more and more narrow, the pressure on the sludge is getting higher and higher.

Then the water is separated from the sludge and flow out from the gap between the moving and fixed plate. The movement of the moving plates and the fixed plates cleans the gap between them and prevent the machine from blockage. The filtered sludge cakes are pushed forward by the shaft and finally discharged from the end.

The screw type sludge dewatering machine configurates exclusive spiral plate for pre-concentration and better for dealing with low concentration sludge.

To improve the shortcomings of gravity type in order to realize efficient concentration of sludge.

Floucculation and concentration operating together, make dewatering easy.

Optimize concentration of original sludge for dewatering with intelligent control valve.

The screw type sludge dewatering machine depends on the volume pressure dehydration, dispensing with drums and other large-sized devices so as to realize a low operation speed, which is only 2-4 revolutions per minute.

Therefore, the machine is able to realize low energy consumption, low water consumption and less noise. The average energy consumption is only 1/8 of the belt type machine, the 1/20 of the centrifuge, with the unit energy consumption is only 0.01-0.1 kwh/kg-DS, being able to reduce the system operation cost of sewage treatment.